A quick return mechanism is an system to produce a resiprocating effect such that time taken by system in return stroke is less time taken by it in the forward stroke.

In quick return mechanism, a circular motion is converted into reciprocating motion just like crank and lever mechanism but it has return stroke time is different from forward stroke time.

This mechanism is used in many machines. Some of them are shaper machines, slotter machines, screw press, mechanical actuator etc.

With the help of quick return mechanism, the time needed to cutting is minimized.

- Explain Crank And Slotted Link Mechanism In Shaper Machine Tool

- Explain Crank And Slotted Link Mechanism In Shaper Machine Diagram

- Explain Crank And Slotted Link Mechanism In Shaper Machines

- Explain Crank And Slotted Link Mechanism In Shaper Machine Parts

The shaping machine is a simple and yet extremely effective machine. It is used to remove material, usually metals such as steel or aluminium, to produce a flat surface. However, it can also be used to manufacture gears such as rack and pinion systems and other complex shapes. Explain with neat sketch working of crank and slotted link quick return mechanism of shaper. State comparison of shaper and planer. What are advantages and disadvantages of shaping and planning as compared to other operations? How stroke length and stroke position can be set on a shaper having crank and slotted link mechanism? Explain with neat. (2) Whitworth quick return mechanism, and (2) Hydraulic shaper mechanism. The crank and slotted link mechanism is discussed as under. Crank and Slotted Link Mechanism. In crank and slotted link mechanism (Fig.), the pinion receives its motion from an individual motor or overhead line shaft and transmits the motion or power to the bull gear.

Types of Quick Return Mechanism:-

1 Hydraulic Drive:

Hydraulic drive mechanism is one of the mechanism used in shaper machine. In this mechanism, the ram is moved forward and backward by a piston moving in a cylinder placed under the ram.

This machine consists of a constant discharge oil pump, a cylinder , a valve chamber and a piston. The piston ram is bolted to the the ram body.

Hydraulic fluid is used in hydraulic quick return mechanism for the movement of ram.

Working of Hydraulic Drive :-

In hydraulic drive, there is a tank at the bottom which contains the hydraulic fluid. This tank is also known as oil reservoir.

At first the oil from the reservoir.

This oil is passed through the valve chamber present in the right of the oil cylinder exerting pressure on the piston.

Any oil present in the left side of the piston is discharged to the reservoir through the throttle valve.

At first the fluid in the tank is pumped out and this fluid passes through the passage present in the right side of the cylinder .

This fluid exerts pressure on the piston and the ram of the machine performs forward stroke.

When the ram moves forward, the lever changes its position and hits the reversing dog. As the lever changes its position, the three valves connected to the lever also change their position and now the oil can pass through the passage present in the left side of the cylinder.

After the forward stroke is completed, the valves changes its position and now the pumped fluid from the reservoir moves from the passage present in the left side of the piston. Also, the passage through which the oil return to the reservoir opens and get connected to the right passage and the fluid present on the right side of the piston is discharge to the reservoir.

As the fluid moves towards the left side of the piston, the piston which is attached to the ram moves towards right and return stroke is performed by the ram.

At the end of the return stroke, another dog hit against the lever and the direction of the lever as well as the stroke changes. In this way, the forward and the return stroke of the ram is repeated.

The quick return takes place due to difference in the stroke volume of cylinder at both ends. The volume of passage at the left side is less than the volume of the passage on the right side. As the pump is constant discharge pump, same amount of oil will be passed on the both passage. So the pressure n the passage with less volume will be more and the return stroke will be faster than the forward stroke.

The cutting speed can be controlled by controlling the flow of oil which can be controlled by using the throttle valve.

When the throttle valve is lost the excess valve is cut through the relief valve to the reservoir maintaining uniform pressure during the cutting stroke.

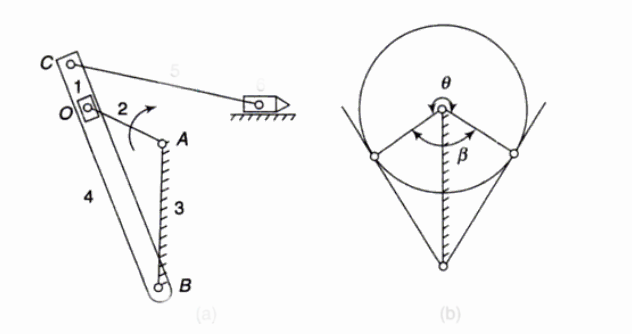

2. Whitworth Quick Return mechanism :-

This mechanism changes the rotary motion to oscillatory motion like the crank and lever mechanism.

The difference between the crank and lever mechanism and Whitworth mechanism is that in whitworth mechanism the return stroke is faster than the forward stroke while in the crank and lever mechanism the forward stroke is of same speed as that of return stroke.

Parts used in Whitworth mechanism :-

1) Slotted Bar.

2) Slider

3) Crank – It will rotate.

Whitworth quick return mechansim is the second inversion of slider crank mechanism in which the crank is fixed.

In this mechanism, the Slider in slotted bar is connected to the crank. When the crank rotates, the slider will slide inside the slotter bar and the slotted bar will oscillate. As the slotted bar oscillate, the ram will move in forward and backward direction.

The return stroke or ideal is faster than the forward stroke in this mechanism.

In the above figure AP is the slotted bar and link 1, CD is link 2, AC which is crank is link 3 and link 4 is the slider.

In this mechanism the link CD i.e link 2 forming the turning pair is fixed as shown in the figure above.

The crank AC revolves with uniform velocity with its centre at A.

A sliding block attached to the crank pin at B slides along the slotted bar AP and thus causes Ap to oscillate about the pivoted pint A. A short link PR transmits the motion from AP to the ram which carries the tool and thus forward stroke and backward stroke is obtained.

The crank needs to rotate through an angle of ( β ) for the forward stroke and it needs to rotate through an angle of ( α ) for forward stroke.

As crank moves with uniform angular velocity , time taken to cover angle α will be less than the time taken to cover angle β. Hence time taken in return stroke will be less than time taken in forwaed stroke. In this way, the quick return mechanism works.

3) Crank and Slotted Link Mechanism:-

In crank and slotted link mechanism. The power is transmitted to the bull gear by a pinion which recieves its power from an individual motor.

In a two gear system, the smaller gear is called pinion and the larger gear is called bull gear.

Working of Crank and Slotted Link Mechanism:-

The radial slide is bolted to the centre of the bull gear. This radial slide carries a sliding block into which the crank pin is fitted.

As the bull gear will rotate, the crank will revolve at uniform speed.

The sliding block which is mounted upon the crank pin is fitted upon the crank pin is fitted within the slotted link. This slotted link is pivoted uponat its bottom end attached to the frame of column. The upper end of the sliding link is bifurcated and attached to the ram block by a pin.

When the bull gear rotates, the crank pin revolves at a uniform speed. The sliding block fastened to the crank pin will rotate on the crank pin circle and at the same time this slider will slide up and down in the sliding link.

As the slider will move inside the sliding link, it will provide a rocking movement to the sliding link and this movement will be transferred to the ram providing it a resiprocatory motion.

Hence the rotary motion of the bull gear is converted into resiprocatory motion of ram.

A quick return mechanism is an apparatus to produce a reciprocating motion in which the time taken for travel in return stroke is less than in the forward stroke. It is driven by a circular motion source (typically a motor of some sort) and uses a system of links with three turning pairs and a sliding pair.

Quick return is a common feature of tools in which the action is performed in only one direction of the stroke, such as shapers and powered saws, because it allows less time to be spent on returning the tool to its initial position.

History[edit]

During the early-nineteenth century, cutting methods involved hand tools and cranks, which were often lengthy in duration. Joseph Whitworth changed this by creating the quick return mechanism in the mid-1800s.[1] Using kinematics, he determined that the force and geometry of the rotating joint would affect the force and motion of the connected arm. From an engineering standpoint, the quick return mechanism impacted the technology of the Industrial Revolution by minimizing the duration of a full revolution, thus reducing the amount of time needed for a cut or press.

Applications[edit]

Quick return mechanisms are found throughout the engineering industry in different machines:

- Screw press

- Power-driven saw

- Mechanical actuator

- revolver mechanisms

Design[edit]

The disc influences the force of the arm, which makes up the frame of reference of the quick return mechanism. The frame continues to an attached rod, which is connected to the circular disc. Powered by a motor, the disc rotates and the arm follows in the same direction (linear and left-to-right, typically) but at a different speed. When the disc nears a full revolution, the arm reaches its furthest position and returns to its initial position at a quicker rate, hence its name. Throughout the cut, the arm has a constant velocity. Upon returning to its initial position after reaching its maximum horizontal displacement, the arm reaches its highest velocity.

The quick return mechanism was modeled after the crank and slider (arm), and this is present in its appearance and function; however, the crank is usually hand powered and the arm has the same rate throughout an entire revolution, whereas the arm of a quick return mechanism returns at a faster rate. The 'quick return' allows for the arm to function with less energy during the cut than the initial cycle of the disc.

Specifications[edit]

Explain Crank And Slotted Link Mechanism In Shaper Machine Tool

When using a machine that involves this mechanism, it is very important to not force the machine into reaching its maximum stress capacity; otherwise, the machine will break. The durability of the machine is related to the size of the arm and the velocity of the disc, where the arm might not be flexible enough to handle a certain speed. Creating a graphical layout for a quick return mechanism involves all inversions and motions, which is useful in determining the dimensions for a functioning mechanism.[2] A layout would specify the dimensions of the mechanism by highlighting each part and its interaction among the system. These interactions would include torque, force, velocity, and acceleration. By relating these concepts to their respective analyses (kinematics and dynamics), one can comprehend the effect each part has on another.

Mechanics[edit]

In order to derive the force vectors of these mechanisms, one must approach a mechanical design consisting of both kinematic and dynamic analyses.

Kinematic Analysis[edit]

Breaking the mechanism up into separate vectors and components allows us to create a kinematic analysis that can solve for the maximum velocity, acceleration, and force the mechanism is capable of in three-dimensional space.[3] Most of the equations involved in the quick return mechanism setup originate from Hamilton's principle.[4]

The position of the arm can be found at different times using the substitution of Euler's formula:[5]

into the different components that have been pre-determined, according to the setup.

Explain Crank And Slotted Link Mechanism In Shaper Machine Diagram

This substitution can solve for various radii and components of the displacement of the arm at different values. Trigonometry is needed for the complete understanding of the kinematic analyses of the mechanism, where the entire design can be transcribed onto a plane layout, highlighting all of the vector components.

An important concept for the analysis of the velocity of the disc relative to the arm is the angular velocity of the disc:

[4]

If one desires to calculate the velocity, one must derive the angles of interaction at a single moment of time, making this equation useful.

Dynamic Analysis[edit]

In addition to the kinematic analysis of a quick return mechanism, there is a dynamic analysis present. At certain lengths and attachments, the arm of the mechanism can be evaluated and then adjusted to certain preferences. For example, the differences in the forces acting upon the system at an instant can be represented by D'Alembert's principle.[6] Depending on the structural design of the quick return mechanism, the law of cosines can be used to determine the angles and displacements of the arm. The ratio between the working stroke (engine) and the return stroke can be simplified through the manipulation of these concepts.[7]

Despite similarities between quick return mechanisms, there are many different possibilities for the outline of all forces, speeds, lengths, motions, functions, and vectors in a mechanism.

See also[edit]

- Crank (mechanism) – Simple machine transferring motion to or from a rotaing shaft at a distance from the centreline

Explain Crank And Slotted Link Mechanism In Shaper Machines

References[edit]

Explain Crank And Slotted Link Mechanism In Shaper Machine Parts

- ^'Sir Joseph Whitworth'. The Whitworth Society. Retrieved January 31, 2016.

- ^Podhorodeski, Ron (March 2005). 'Quick-Return Mechanism Design and Analysis Projects'. International Journal of Mechanical Engineering Education.

- ^Stumph III, Herbert Edward (May 2000). 'Kinematic Synthesis of Four and Six Link Mechanisms Used in Mechanical Presses'(PDF). University of Dayton, School of Engineering.

- ^ abBeale, D. G.; Scott, R. A. (1990-09-08). 'The stability and response of a flexible rod in a quick return mechanism'(PDF). Journal of Sound and Vibration. 141 (2): 277–289. Bibcode:1990JSV...141..277B. doi:10.1016/0022-460X(90)90840-V. hdl:2027.42/28391.

- ^Echempati, Raghu (June 23, 2013). 'Quick Return Mechanism Revisited'. American Society for Engineering Education.

- ^Patel, Shrikant R. (May 2013). 'Dynamic Analysis of Quick Return Mechanism Using MATLAB'(PDF). International Journal of Engineering Science and Innovative Technology (IJESIT).

- ^Hsieh, Wen-Hsiang (September 2009). 'A Study on a Novel Quick Return Mechanism'(PDF). Transactions of the Canadian Society for Mechanical Engineering. 33 (3).